Some Of Inventory Management

Table of ContentsThe Single Strategy To Use For Inventory ManagementHow Inventory Management can Save You Time, Stress, and Money.Get This Report about Inventory ManagementThe Best Strategy To Use For Inventory Management

There are 2 major techniques of monitoring stock: regular as well as perpetual. The primary distinction between these is just how typically information is updated. Despite just how often you track supply, you might intend to use among the following stock management techniques: ABC Evaluation, ABC (Always Better Control) Analysis is supply management that separates different things into three categories based on pricing as well as is separated right into teams A, B, or C.The items in the B group are relatively less expensive compared to the A classification. And also the C category has the most affordable products of all three. EOQ Version, Economic Order Amount is a strategy utilized for preparation as well as buying an order amount. It entails choosing pertaining to the amount of stock that should be put in supply at any type of given time. Inventory Management.

FSN Method, This technique of stock control describes the procedure of monitoring all the products of stock that are not used often or are not needed constantly. They are then classified right into 3 various groups: fast-moving supply, slow-moving supply, and also non-moving supply. JIT Approach, Just In Time inventory control is a process utilized by producers to regulate their supply degrees.

Some Known Incorrect Statements About Inventory Management

VED Evaluation, VED is a strategy made use of by companies to manage their inventory. It mostly refers to the management of crucial and preferable extra parts. The high degree of inventory that is required for manufacturing normally justifies the low inventory for those parts. Among one of the most essential aspects that a business should take into consideration is the accuracy of the details provided in its inventory data sources.

Wrike's item launch automation assists speed up item launches with a structured strategy.

6 Easy Facts About Inventory Management Explained

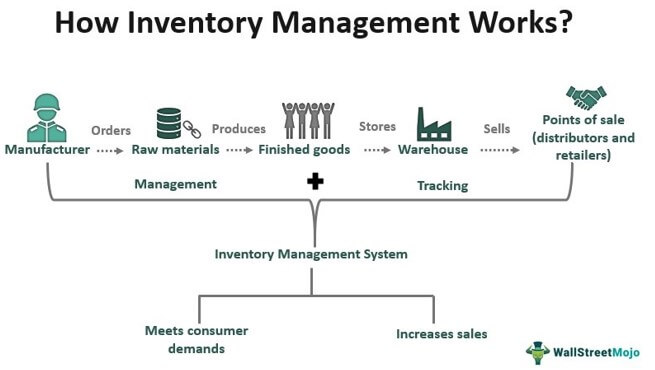

Supply administration describes the procedure of purchasing, saving, using, and offering a business's supply. This includes the monitoring of basic materials, elements, as well as completed products, in addition to warehousing as well as handling of such things. There are various kinds of stock pop over to this site management, each with its advantages and disadvantages, depending upon a business's requirements.

Inventory administration attempts to successfully enhance stocks to prevent both gluts and also lacks. 4 major supply administration methods consist of just-in-time administration (JIT), materials demand planning (MRP), financial order amount (EOQ), as well as days sales of inventory (DSI). There are pros as well as disadvantages per of the approaches, assessed below. A firm's stock is one of its most important assets.

A scarcity of inventory when and where it's required can be incredibly detrimental (Inventory Management). At the exact same time, supply can be taken an obligation (if not in an audit sense). A huge stock brings the threat of wasting, burglary, damages, or changes popular. Stock needs to be insured, and if it is not sold in time it might have to be thrown away at clearance pricesor merely destroyed.

Little organizations will certainly often maintain track of stock by hand and establish the reorder points and amounts utilizing spread sheet learn the facts here now (Excel) solutions.

Examine This Report about Inventory Management

Appropriate stock management strategies differ depending upon the sector. An oil depot is able to keep large amounts of stock for extensive amount of times, permitting it to wait for need to select up. While storing oil is costly and also riskya fire in the U.K. in 2005 caused numerous extra pounds in damage and finesthere is no risk that the stock will ruin or head out of design.

For companies with complex supply chains as well as making procedures, balancing the threats of inventory gluts as well as lacks is especially hard. To attain these balances, firms have established numerous approaches for inventory administration, consisting of just-in-time (JIT) and also products need planning (MRP). Some business, such as economic solutions companies, do not have physical supply as well as so has to count on solution process administration.

Stock has to be physically counted or gauged prior to it can be placed on an equilibrium sheet. Firms commonly maintain sophisticated inventory management systems efficient in tracking real-time inventory levels. Inventory is made up making use of one of 3 approaches: first-in-first-out (FIFO) setting you back; last-in-first-out (LIFO) setting you back; or weighted-average costing. A stock account read this article typically includes 4 different groups: Basic material represent different products a business purchases for its manufacturing procedure.

Operate in process (additionally referred to as goods-in-process) stands for raw materials in the process of being changed right into an ended up item. Finished products are finished products readily available for sale to a company's clients. Product represents completed goods a firm buys from a supplier for future resale. Relying on the kind of service or item being analyzed, a company will certainly make use of various inventory administration approaches.